|

|

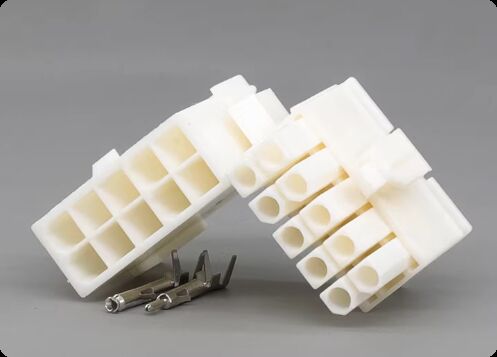

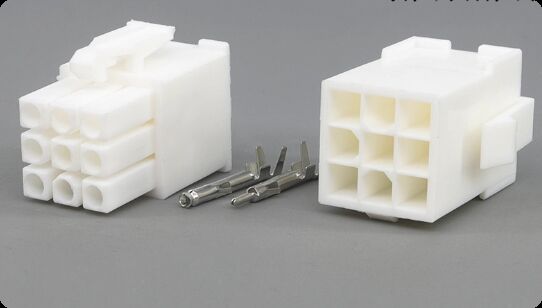

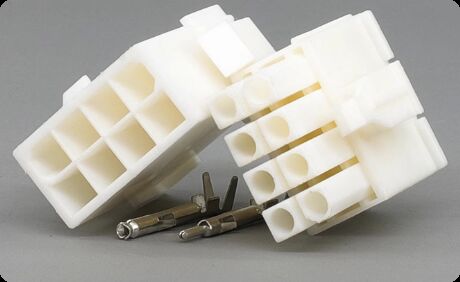

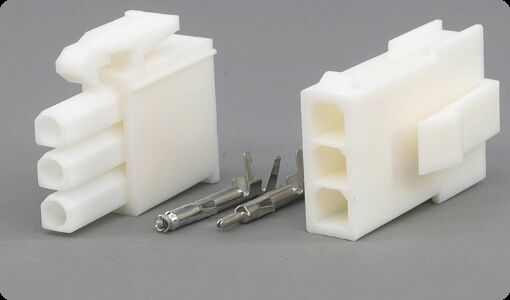

4145 Connector Plug for Servo Motor Terminals, Wire Connector Male and Female Terminal, Plastic Housing, 10 Pins

|

Détails sur le produit:

Conditions de paiement et expédition:

|

| Température de fonctionnement: | -40℃ à +105℃ | Calibre de fil: | 18-24 AWG ou plus AWG 3-12 de diamètre |

|---|---|---|---|

| Type de terminaison: | Sertissage/soudure | matériel: | Métal/Plastique |

| Nom: | Connecteur Moog ITT | Tension nominale: | 1000V |

| Type de connecteur: | Servomoteur | Placage de contact: | Épingle en argent Épingle dorée |

4145 Connector Plug for Servo Motor Terminals, Wire Connector Male and Female Terminal, Plastic Housing, 10 Pins

![]()

![]()

![]()

![]()

Product Description:

Servo Motor Connectors are essential components designed to ensure reliable and efficient connections in various servo motor systems. These connectors are specifically engineered to support the high-performance demands of Brushless Servo Motor applications, DC Servo Motor Drive units, and AC Servo Servo Driver setups. By providing secure and stable electrical connections, they play a critical role in maintaining the precision and responsiveness required in modern motion control systems.

One of the key features of these Servo Motor Connectors is their versatile termination type. They offer both crimp and solder termination options, allowing for flexible installation methods depending on the application requirements and technician preferences. Crimp termination provides a fast and secure connection with minimal equipment, ensuring consistent electrical contact and mechanical strength. On the other hand, solder termination offers a more permanent connection, ideal for situations where vibration resistance and long-term reliability are paramount.

The connectors are designed with a Moog gender configuration, which is widely recognized in the industry for its compatibility and standardized interface. This gender specification ensures seamless integration with a broad range of servo motor controllers and drives, including those used in Brushless Servo Motor systems, which demand high precision and rapid response times. The Moog connector gender facilitates easy mating and unmating, reducing installation time and minimizing the risk of connection errors.

Constructed from a combination of metal and plastic materials, these Servo Motor Connectors provide an optimal balance of durability, strength, and insulation. The metal components contribute to excellent mechanical robustness and electromagnetic shielding, protecting the signal integrity even in electrically noisy environments commonly encountered in industrial settings. Meanwhile, the plastic parts offer insulation and resistance to environmental factors such as moisture, dust, and temperature fluctuations, enhancing the overall reliability and longevity of the connectors.

Contact plating is another critical aspect of these connectors. They feature silver-plated contacts along with gold-plated pins to ensure superior electrical conductivity and corrosion resistance. Silver plating provides excellent surface conductivity, reducing contact resistance and improving signal transmission quality. The gold plating on the pins further enhances durability by preventing oxidation and wear over repeated mating cycles. This combination of contact plating materials ensures that the connectors maintain consistent performance throughout their service life, which is particularly important for applications involving Brushless Servo Motor systems and sensitive DC Servo Motor Drive electronics.

These Servo Motor Connectors are designed with the specific needs of servo motor systems in mind. Whether used in Brushless Servo Motor applications that require precise torque and speed control, DC Servo Motor Drive systems that demand stable and efficient power delivery, or AC Servo Servo Driver configurations that need robust and reliable connections, these connectors deliver outstanding performance. Their robust design, combined with high-quality materials and precise manufacturing standards, ensures that they can withstand the demanding conditions found in industrial automation, robotics, aerospace, and other high-tech fields.

In summary, the Servo Motor Connectors with crimp and solder termination types, Moog gender configuration, metal and plastic construction, and silver/gold contact plating are indispensable components for any servo motor system. They guarantee reliable electrical connections, resist environmental challenges, and maintain signal integrity, thereby enabling Brushless Servo Motor, DC Servo Motor Drive, and AC Servo Servo Driver systems to operate at their full potential. Investing in these high-quality connectors means enhancing the overall efficiency, durability, and performance of your servo motor applications.

Features:

- Product Name: Servo Motor Connectors

- Termination Type: Crimp/Solder for secure and reliable connections

- Gender: Moog compatible

- Mounting Type: Panel Mount and Cable Mount options available

- Current Rating: Suitable for Battery-powered applications

- Operating Temperature Range: -40℃ to +105℃ for harsh environments

- Ideal for High Torque DC Servo Motor applications

- Compatible with Electro Hydraulic Servo systems

- Supports AC Servo Motor Driver connections

Technical Parameters:

| Product Name | Moog ITT Connector |

| Connector Type | Servo Motor |

| Contact Plating | Silver Pin, Golded Pin |

| Operating Temperature | -40℃ To +105℃ |

| Application | Industrial Automation including AC Brushless Servo Motor, High Torque DC Servo Motor |

| Gender | Moog |

| Mounting Type | Panel Mount / Cable Mount |

| Wire Gauge | 18-24 AWG Or More, AWG 3-12 Diameter |

| Termination Type | Crimp / Solder |

| Insulation Resistance | 10PIN |

Applications:

The NO MARK servo motor connector, model number servo motor connector, is a premium-quality product originating from China, designed specifically for industrial automation applications. Certified by CE and ISO9001, this connector ensures high reliability and performance, meeting stringent international standards. With a minimum order quantity of 100 units and a supply ability of 1000 pieces per day, it is an ideal choice for large-scale industrial projects requiring efficient and durable connections.

This servo motor connector is perfectly suited for a variety of application occasions and scenarios, especially in systems involving Electro Hydraulic Servo mechanisms. These connectors provide secure and stable connections essential for the precise control and operation of Electro Hydraulic Servo systems, which are commonly used in advanced manufacturing and automation environments. The metal and plastic construction guarantees durability and resistance to harsh conditions, supporting an operating temperature range from -40℃ to +105℃, making it suitable for demanding industrial settings.

In the realm of Hydraulic Brake Motors, the NO MARK servo motor connector offers reliable electrical connections that enhance the performance and safety of braking systems. Hydraulic Brake Motors require connectors that can withstand mechanical stress and environmental challenges, and this product’s robust insulation resistance with a 10PIN configuration ensures stable signal transmission and power delivery. Its compatibility with Moog gender design further expands its usability across different motor types and configurations.

For High Torque DC Servo Motor applications, this connector is indispensable. High Torque DC Servo Motors demand precise and efficient connectivity to maintain their high performance and torque output. The NO MARK servo motor connector supports these requirements perfectly, facilitating efficient power transfer and communication between motor components. Its packaging in carton boxes ensures safe delivery, and with a fast delivery time of 1-3 working days, businesses can maintain minimal downtime during installations or replacements.

Payment for the NO MARK servo motor connector is flexible, accepting T/T and PayPal, which simplifies international transactions. Overall, this product is an excellent solution for industries seeking reliable, high-quality connectors for Electro Hydraulic Servo systems, Hydraulic Brake Motors, and High Torque DC Servo Motors, ensuring optimal performance and longevity in industrial automation settings.

Customization:

Our Servo Motor Connectors, branded as NO MARK and model number servo motor connector, are designed to meet the demanding needs of industrial automation applications. Manufactured in China and certified with CE and ISO9001 standards, these connectors ensure high quality and reliability for your Brushless Servo Motor and AC Servo Drive systems.

We offer product customization services tailored to your specific requirements, including wire gauge options from 18-24 AWG or more, accommodating AWG 3-12 diameter cables to suit various configurations. The connectors feature a 10PIN insulation resistance design and are capable of handling battery-level current ratings, making them ideal for both Brushless Servo Motor and AC Servo Drive applications.

Our minimum order quantity is 100 units, with a supply ability of 1000 pcs/day, ensuring prompt availability. All products are carefully packaged in carton boxes to guarantee safe delivery, with a typical delivery time of 1-3 working days.

Payment terms are flexible, accepting T/T and PayPal for your convenience. The Moog ITT Connector name represents our commitment to quality and performance in the servo motor connector market.

Contact us to customize your servo motor connectors and enhance your AC Servo Drive solutions with reliable and efficient connectivity products.

Support and Services:

Our Servo Motor Connectors are designed for reliable and efficient connection in servo motor applications. For technical support, we provide comprehensive assistance including product selection guidance, installation instructions, troubleshooting, and maintenance tips to ensure optimal performance.

We offer detailed datasheets and technical documentation to help you understand the specifications and compatibility of our connectors. Our support team is ready to assist with any custom requirements or special configurations needed for your application.

Additionally, we provide repair and replacement services to minimize downtime. Regular updates and firmware compatibility information are also available to keep your servo motor systems running smoothly.

For service inquiries, please refer to the warranty terms and conditions included with your product purchase to understand coverage and support options.

Personne à contacter: Zhou

Téléphone: +8613316962478

-

Les connecteurs de servomoteur ASD-MDBT0100

-

Connecteurs de câbles de servomoteur de type M23 M40 E P 17 broches 12 broches

-

SM-6E 6E SM Servo connecteurs ensemble complet IEEE1394 6 pièces féminines de base

-

SM-6P servo MOLEX SM6P 1394 6 PIN Male Female Connector

-

Connecteurs de servomoteur J17S-06FMH-7KL-1M-CF PA66 avec ressort Stell

-

Applicable to Delta AB/B2/B3/A2/A3 servo drives CN1 connector for encoder, CN2 plug for motor